Balconies are a staple in apartment complexes, hotels, and romantic Medieval literature. They offer a place for a smoke break, a sip of coffee, or a lengthy soliloquy spoken in Iambic Pentameter about a love forbidden by deep familial feuds. Balconies should be peaceful areas of refuge.

They should not make your apartment leak!

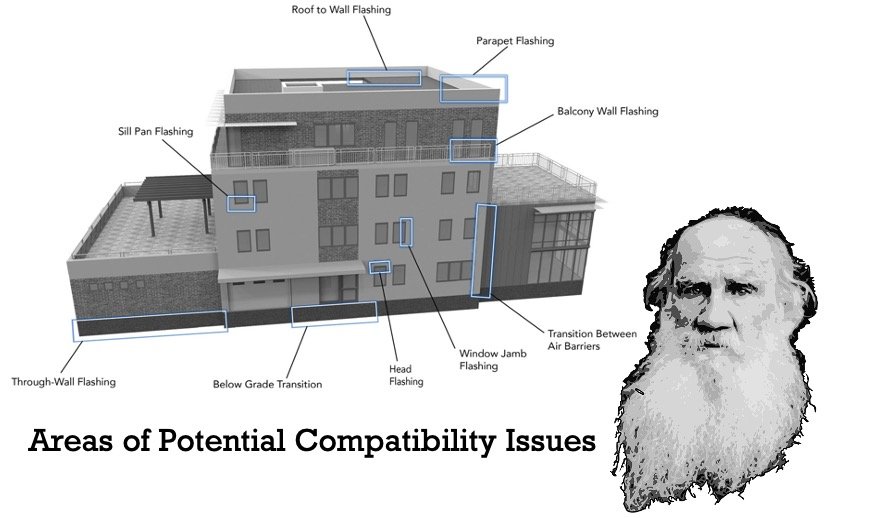

This seems like it should be a no brainer. Just slope the balcony away from the structure! Any rainwater that collects on it will be spirited away. However there are sometimes competing forces in construction that can make this seemingly easy principle difficult to follow. While the balcony is usually the purview of the architect, the structural engineer, the contractor and even the concrete itself, all have a roles to play.

Architects typically shoot for a 1% grade. But a number of external factors can cut into this already razor thin margin. The structural engineer might want a thicker slab at the perimeter. The contractor’s finishing might miss the mark.

The contractor is responsible for getting within these tolerances but like a rebellious Capulet, the concrete might not always listen. Concrete mix design, placement and environmental conditions can potentially allow the concrete to curl or otherwise deform. If any of these variables are severe enough, they can take that 1% drainage plane that you started with and start turning it back into the building.

A 2% slope, usually a 1/4” drop per foot, is more ideal for positive drainage and gives you a little more room for error. Leaking balconies seem like small issue but they can lead to moldy carpets, door replacements and premature deterioration of the concrete itself. It may not totally kill your building but “'tis enough, 'twill serve.”

If you already find yourself with reverse sloped balconies, then there are measures you can take.

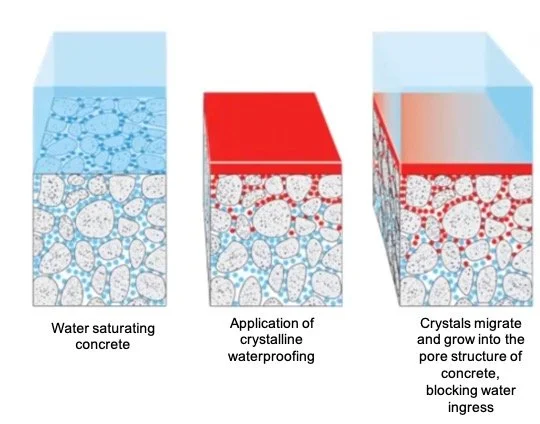

Cementitious patching materials can help with drainage while waterproof coatings can help mitigate moisture intrusion.

And now a summation written in Iambic Pentameter*:

The rain falls down and flows inside! Dismay!

Fair Slope, you elude my grasp! Oh why

Did I not plan for curls in my concrete?

What can be done? What salve soothes this mistake?

*proudly not written by ChatGPT thankyouverymuch…**

**but I did check my work with it…